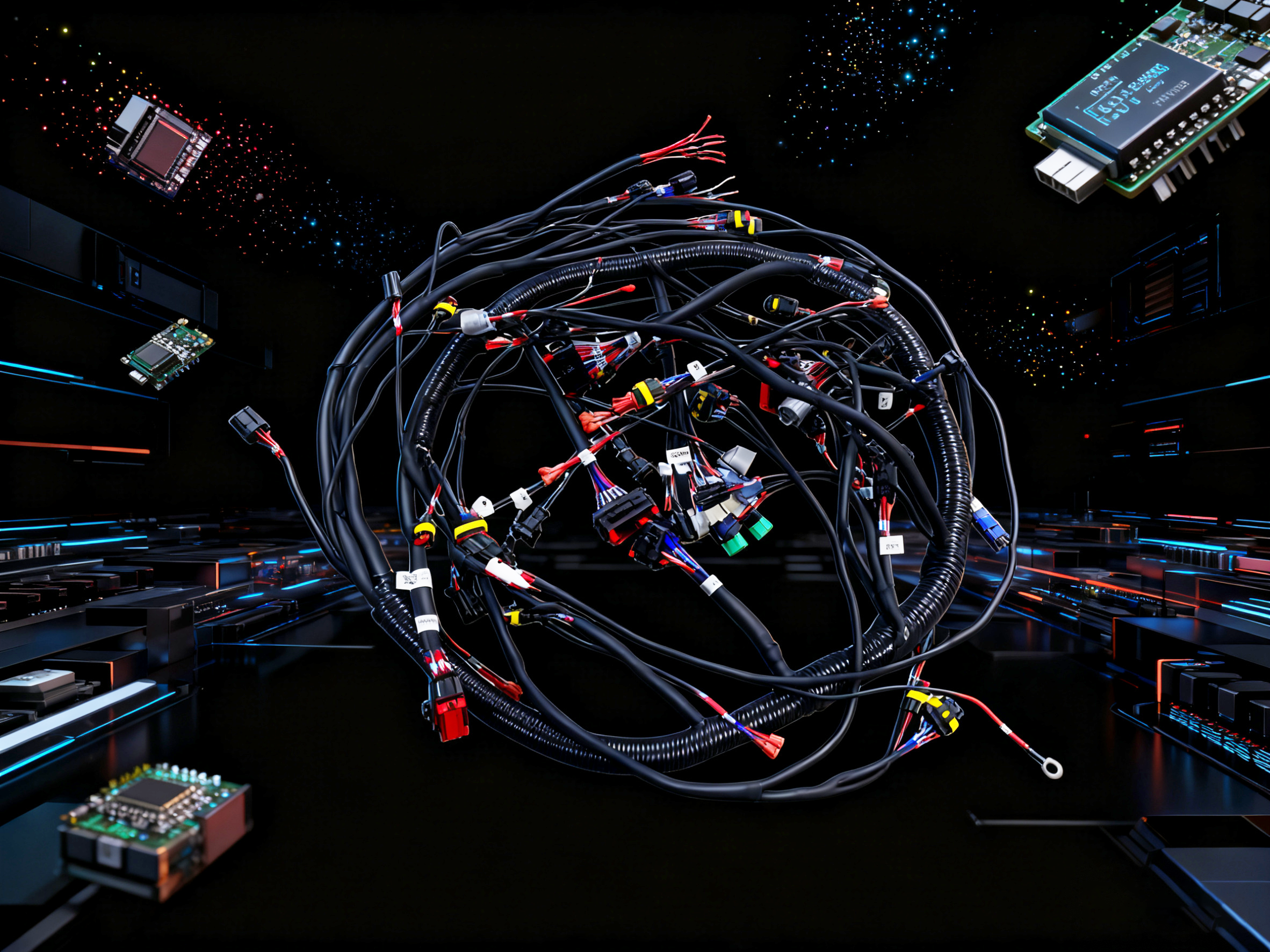

In automated logistics systems, AGVs are the silent backbone. The crucial component ensuring their stable operation is the often-unseen wiring harness. At Fengle Electronics, we understand this deeply. Therefore, every AGV-specific wiring harness destined for our customers must pass six rigorous tests at our quality inspection center, guaranteeing persistent and stable performance even under demanding operating conditions.

1. Continuity Test: Ensuring a "Faultless" Foundation

This is the most fundamental yet critical first step. We utilize continuity testers to conduct 100% inspection of every circuit within the harness.

Fengle Standard: It's not just about "pass" or "fail." We also measure loop resistance, ensuring it remains within an exceptionally low design tolerance, minimizing energy loss and signal attenuation from the source.

2. Flex Endurance Test: Simulating Longevity Under Duress

AGVs require frequent turning and movement during operation, necessitating extremely high flexibility and durability in their harnesses, especially cables for tow-type AGVs.

Fengle Standard: Our harnesses undergo repeated bending on specialized equipment at cycles far exceeding industry standards. Post-test, the insulation must show no cracks, conductors must remain unbroken, and electrical performance must stay stable.

3. Thermal Cycling Test: Confronting Temperature Challenges in Complex Environments

From chilly warehouses to hot workshops, AGVs face temperature variations. Harness materials can age due to thermal expansion and contraction, potentially degrading performance.

Fengle Standard: Harnesses are placed in thermal chambers and subjected to multiple rapid cycles between -30°C and +105°C (or as customer specified). After testing, insulation must not become brittle or sticky, and terminals must not oxidize, preventing poor contact.

4. IP (Ingress Protection) Rating Test: Ensuring Stability in Damp/Dusty Conditions

Even indoors, AGVs might encounter moisture from floor washing or airborne dust.

Fengle Standard: We apply IP65 standards, testing connectors with spray, splash, or dust resistance tests. Critical components often require IP67 rating, meaning complete dust protection and ability to withstand temporary immersion, providing robust protection for AGVs.

5. Oil/Chemical Resistance Test: Withstanding Accidental Corrosion

In industrial settings, harnesses may contact lubricants, hydraulic oils, or other chemicals.

Fengle Standard: Harness samples are immersed in specified oils or chemicals for a set duration. Afterwards, they are inspected for deformation, material degradation, and re-tested electrically to ensure uncompromised functionality.

6. Vibration Test: Preventing "Jolt-Induced" Failures

Continuous vibration generated during AGV travel can, over time, lead to loose terminals or wire chafing.

Fengle Standard: Harnesses are secured on vibration test platforms and subjected to vibrations of varying frequencies and durations. Post-test, all terminals must remain secure, clamps and ties undamaged or loose, and electrical performance must remain unchanged.

At Fengle Electronics, we believe that exceptional quality stems from rigorous attention to detail. These six tests are just a snapshot of our comprehensive quality assurance system. We fully understand that what you are selecting is not merely a wiring harness, but a critical guarantee for the efficient and uninterrupted operation of your entire AGV fleet.

What we deliver is more than just a product—it is a reliable commitment.

Feel free to contact us at any time to obtain more detailed test standards or to discuss customized wiring harness solutions tailored to your specific application scenarios.